Choosing a wiper system for heavy-duty vehicles in 5 steps

There is a wide range of heavy-duty vehicles operating in very challenging conditions where every component plays a crucial role in ensuring optimal performance. One often overlooked aspect is the wiper system. Choosing the right wiper system can make all the difference in navigating specialized terrains with precision and safety.

When referring to heavy-duty vehicles, we mean vehicles used in:

- forestry

- agriculture

- airports

- harbours

- building sites, or similar.

A reliable windshield wiper system can make a major difference, therefore understanding what to consider when choosing one is crucial.

1) Window size and shape

Along with the area to be cleaned, the size and shape of the heavy-duty vehicle's window is a key factor for choosing a wiper system. Ask yourself where the wiper motor will be mounted and what kind of sweep coverage you need. There may be space limitations that force an off-center placement, but in most cases, mounting the wiper center above or center below the window provides the best coverage.

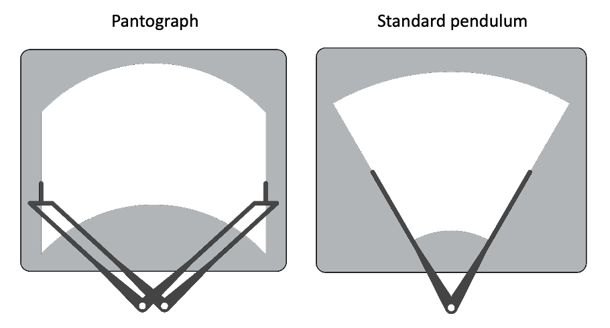

Two common layouts for wiper systems are the Pantograph and the Standard pendulum.

- The Pantograph is preferred for tall and narrow windows.

- The Standard pendulum is better for wide and short windows.

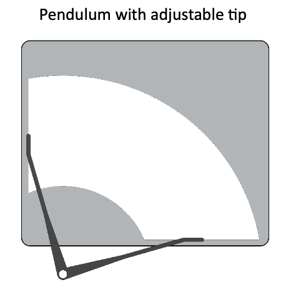

When mounting a wiper motor off-center, a Standard pendulum with an adjustable tip may be necessary.

Utilizing a wiper configurator at this stage is wise, and mapping out the line of sight for the window is crucial.

2) Arms and blades

Naturally, a larger window will require long arms and blades for optimal visibility. Long arms and blades create more friction, and because of this you might need a powerful wiper motor, maybe up to 50 Nm torque range.

When it comes to Pantograph arms, the motors that you can choose can both be dual-drive or single-drive. Dual-drive systems are generally preferred because the wiper motor drives both arms equally. Single drive means that the wiper motor drives one arm and the other arm serves as a support.

Surface treatments for the arms are more of an aesthetic option, with black-painted arms being the most common to avoid sun reflections. The most important choice in this matter is that the wiper arms are made of stainless steel.

Once the length of the arm and blade is determined, you can select the right wiper motor.

3) Wiper motors

For finding a matching wiper motor for your heavy-duty vehicles, you have to consider the outer conditions in which the wiper motor is supposed to perform. Those include parameters like low temperature, snow, and debris, which all add friction to the system. In such cases, we advise you to choose a strong motor.

If the wiper motor is exposed to water or humidity, you should select a motor that is rated IP65 or higher (parts exposed to water should always be made of stainless steel).

To ensure flexibility and work with fewer part numbers, choose a wiper motor with easily adjustable parking positions and sweep angles ranging from 45°-110°.

Last but not least, consider factors like material, bulkhead thickness, voltage, speed, and system operation.

4) Wiper control

Once the wiper motor is selected, you should focus on how to operate it. For systems with two or more wiper motors, synchronization is essential, because this is the only way to start the sweep simultaneously.

If you even desire features like dual speed, intermittent speed, and washing, we recommend a proper wiper control system. Depending on the model, options range from a single switch operation to a full control panel operation.

Our advice in this case is to ensure that the operator/driver can focus on the job and critical tasks that might come along with it - and not on operating the wipers.

5) Accessories

Finally, consider adding accessories such as spray nozzles, bulkhead fittings, water tanks, and pumps to complete the system.

Conclusion

Choosing the right wiper system for heavy-duty vehicles involves an evaluation of environmental conditions, and durability requirements. By investing time in selecting the most suitable wiper system, operators of special vehicles can significantly enhance safety, efficiency, and overall performance in their respective domains.

All the factors above may however limit the list of available models for your heavy-duty vehicle. In this case, we advise you to use our wiper configurator that lets you type in different parameters and "play around" with measures and surface treatments.