3 upgrades to be released for folding bracket Robust

At ROCA Industry, we constantly evaluate our products and wherever needed, we upgrade and improve. In an upcoming release, our folding bracket Robust will be modified in three differents aspects. Read more about them in this blog post.

For over a decade now, our folding brackets make the perfect companion in all kinds of applications and environments. As the "strong brother" of Rakego, the two-in-one bracket Robust is appreciated all over the world.

After customer feedback and internal evaluation, we now will roll out the Robust folding bracket with minor upgrades.

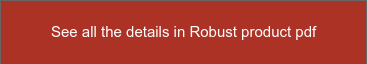

Upgrade 1: Recess shape riveting

In the older version, scratches on the link arm could occur due to protude shape riveting and a too narrow gap between the back plate and the link arm. This will now be avoided due to a larger gap.

This change applies to all Robust series (soft and black): 907660 (Robust L), 907665 (Robust XL) and 907655 (Robust M).

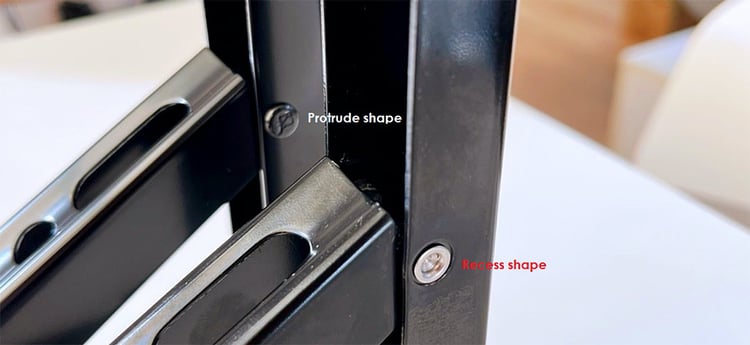

Upgrade 2: Reduced height of release lever

The height of the release lever has been reduced by 6,3 mm. This will completely avoid contact between the release lever and the link arm. The result: In order to reduce the friction between release lever and the arm - and reduce scratches on the release lever - 3M tape will no longer be required.

This change applies to most of Robust (soft and black) models: 907660 (Robust L) and 907665 (Robust XL)

Upgrade 3: Larger drill hole

By enlarging the drill hole, a longer screw driver will not be required for assembly. But still, during the installation process, the bracket must be in folded position for easier installation.

This change applies to most of Robust (soft and black) models: 907660 (Robust L) and 907665 (Robust XL). 907655 (Robust M) already has larger drill holes.