[FAQ] Wiper systems for landbased & heavy-duty vehicles

As Sales Manager for our product range of wiper systems, I get questions about how to choose the right product. This especially when it comes to landbased vehicles, e.g. heavy-duty vehicles. Here I list the most common questions.

Question 1: Where should we mount the wiper to ensure the best sweep coverage of the window?

This of course is depending on the size and shape of the window and what kind of sweep coverage you need. With that being said, mounting the wiper center above or center below the window will in most cases provide the best coverage.

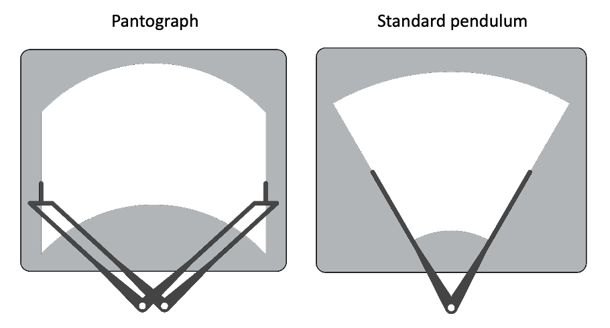

Question 2: Which are the most common layouts for wiper systems on landbased heavy equipment vehicles?

The two common layouts for wiper systems are the Pantograph and the Standard pendulum. The Pantograph is preferred for tall and narrow windows. The Standard pendulum is better for wide and short windows.

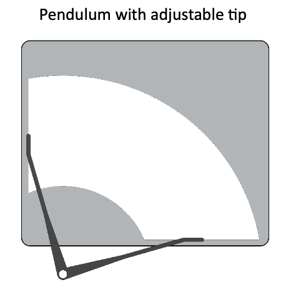

There is also a third, quite popular option that is used when the wiper motor is mounted off-center. This option is based on a Standard pendulum with an adjustable tip.

Question 3: Should I choose black or electropolished wiper arms?

This is a question of taste. Black-painted arms are most common, because they avoid sun reflections. Much more important when it comes to wiper arms is their material. They should be made of stainless steel (even other parts exposed to water should be made of stainless steel).

Question 4: How powerful or strong should my wiper motor be?

The longer the wiper arms and blades, the more friction. So in order to ensure a good sweep, choose a powerful wiper motor. You might need a motor as strong as 50 Nm torque range.

Of course, you should consider the outer conditions in which the wiper motor is supposed to perform. Is it low temperature, snow, and/ord debris? All of these will add friction to the system, which means that you should choose a strong motor.

If you have decided that Pantograph arms are the best option for your vehicle, you can choose both a dual-drive or single-drive motor. In a single drive motor, the wiper motor drives one arm and the other arm serves as a support. According to my own experience, dual-drive systems are better, because the wiper motor drives both arms equally.

Question 5: What other factors should I take into consideration when it comes to wiper motors?

Apart from factors like material, bulkhead thickness, voltage, speed, and system operation, you should ask yourself whether the wiper motor will be exposed to water or humidity. If the answer to that question is "yes", you should select a motor that is rated IP65 or higher. As mentioned above - parts exposed to water should always be made of stainless steel.

Question 6: Do I need a wiper control?

My answer is yes for systems with two or more wiper motors. With a wiper control the wiper arms will be synchronized.

A wiper control system will even give you access to features like dual speed, intermittent speed, and washing. There are lots of products to choose amongst, the cheapest ones build on a single switch operation, the more advanced offer a full control panel operation.

Always make sure that the operator/driver can focus on the job - and not on operating the wipers.

Question 7: Are there tools that can help me find the right solution?

Yes! Use our wiper configurator. This tool lets you type in different parameters and "play around" with measures and surface treatments.